Information Library

Measurement Knowledge <Part 3>

1. What is a digital load cell?

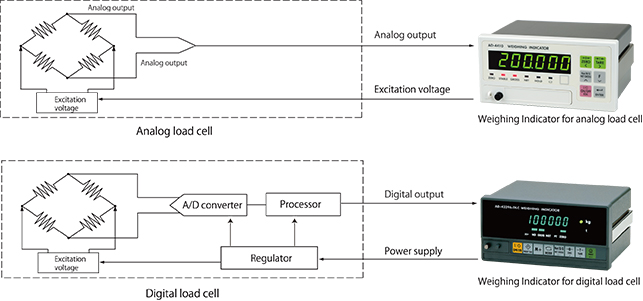

With a typical analog voltage output load cell (hereafter referred to as an analog load cell to distinguish it from a digital load cell), analog to digital (A/D) conversion is performed at the indicator. On the other hand, digital load cells perform A/D conversion using an internal A/D converter. After arithmetic processing to correct peculiarities in the load cell output, a digital signal is sent to the digital load cell indicator.

2. How is the output of a digital load cell different from that of an analog load cell?

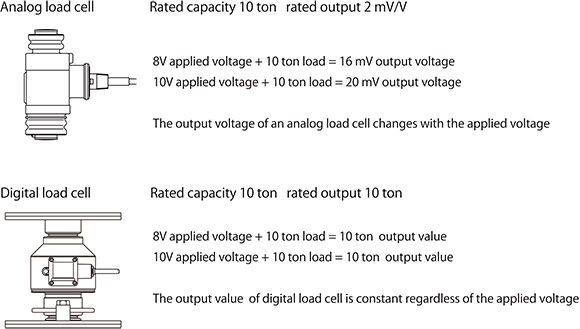

A digital load cell outputs numbers to the indicator while an analog load cell outputs voltage.

The output of analog load cells depends on applied voltage (the voltage supplied to the load cell by the indicator). For example, if a voltage of DC 10V is applied to a load cell with a rated output (the voltage difference of the output when unloaded and the output at the rated capacity) of 2 mV/V and a load at the rated capacity (the maximum load the load cell is designed to measure while maintaining these specifications) is applied, the load cell outputs 20 mV (2 mV x 10V). If the applied voltage is DC 8V, the output is 16 mV (2 mV x 8V). On the other hand, digital load cells output the load applied to the load cell as a digital value (a number), regardless of the applied voltage.

3. What is digital output?

A digital load cell outputs digital (numerical) data to an indicator using serial communication, such as the RS-485 standard, and a Modbus-RTU communication protocol. Besides the load (measurement data), it is possible to acquire overload data of the load, the name of the manufacturer, the machine type, and the serial number as digital values, which is not possible with analog load cells.

4. Are digital load cells compatible?

They are incompatible with analog load cells.

Analog load cells and indicators from different manufacturers can be freely combined. However, it is recommended that digital load cells and indicators from the same company be used.

While there are certainly many basic components in the common digital load cell specifications, companies can add their own unique specifications. Therefore, combining digital load cells and indicators from different companies may create problems and it is necessary to choose products from the same company.

Furthermore, the applied voltage of digital load cells vary by company so care must be taken when using hardware from other companies.

5. What about wiring errors?

Our digital load cells include measures to prevent incorrect wiring.

Furthermore, no problems occur when analog and digital load cells are mistakenly exchanged.

6. What cables are used for digital load cells?

Analog load cell cables cannot be used.

These cables are not designed for serial data communication standards, such as RS-485. Digital load cells use shielded twisted pair cables (duplex communication with 4 wires) for serial data communication.

With digital load cell cables, transmission moves in one direction and DC power (7V to 10V) moves in the other. As cables become longer, one must check for voltage drops in the DC power to ensure that the specified voltage is applied to the digital load cell.

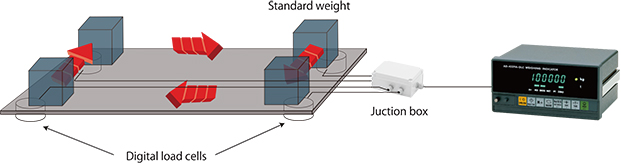

7. Is there a difference in the four corner adjustment methods for analog and digital load cells?

When summing a number of analog load cells to create a balance, the analog output (mV/V) and output resistance are adjusted by adjusting the resistance in the junction box. Generally, off-center placement error correction for each load cell is also performed in the junction box. With digital load cells, however, it is not necessary to adjust the output resistance and off-center placement error is digitally corrected at the indicator. This reduces calibration work and labor versus analog load cells.

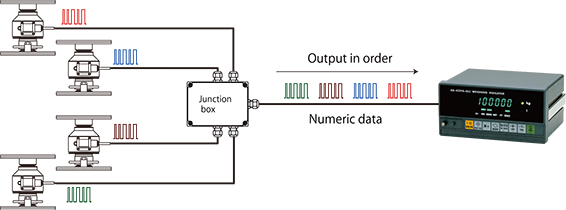

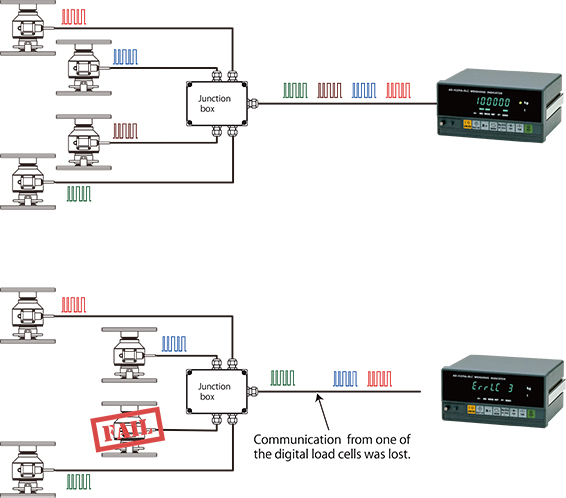

8. Is it easy to identify which digital load cell is malfunctioning?

With analog load cells, it is difficult to detect that one of the cells is malfunctioning. However, this is easy with digital load cells because the signal of each cell is acquired separately.

Because each load cell outputs its own individual signal, the indicator can easily identify a malfunctioning digital load cell that is not sending a signal.